AE

Email: sales@boninscaffolding.com

WhatsApp: +86 136 4619 6162

AE

Email: sales@boninscaffolding.com

WhatsApp: +86 136 4619 6162

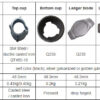

Cuplock scaffolding parst bottom cup is made of pressed steel. All the cups are well made for your production/manufacturing use. Competitive price and fast delivery.

Unit weight 0.2kg.

Surface finish: self color

Package: bags or steel pallet

Contact us today to get a quote or to discuss your custom requirements. We supply reliable scaffolding parts for projects of any scale.

Cuplock scaffolding is a popular and versatile modular scaffolding system used extensively in construction, industrial, and access applications. Its key characteristic is its unique “cup” locking mechanism, which allows for quick and efficient assembly and disassembly without the need for loose pins, bolts, or wedges. CupLock System Scaffolding is easy to assemble and improves labor productivity. This makes our CupLock System Scaffold one of the most used and recognized CupLock scaffolding for sale on the market today.

A circular node point allows up to four horizontal components to connect to a vertical standard with a single action. Ledger blades insert into the bottom cup, and the top cup slides down and rotates to secure them firmly, often requiring only a hammer.

Components are typically made from hot-dip galvanized, high-grade steel (e.g., S355), ensuring durability, corrosion resistance, and high load capacities.

The scaffolding industry worldwide widely trusts and prefers Cuplock scaffolding due to these compelling advantages.